Commercial laundry equipment plays a silent but powerful role in many industries. From hotels and hospitals to gyms, salons, and laundromats, washing machines work nonstop to keep operations running smoothly. When one of these machines fails, productivity can drop instantly, customers become dissatisfied, and losses begin to add up. This is why commercial washing machine repair is not just a technical service, but a critical business necessity. Understanding why breakdowns occur so often, how to prevent them, and when to call professionals can protect your investment and keep your operations steady.

The Demands Placed on Commercial Washing Machines

Unlike residential units, commercial washing machines operate under extreme pressure. They run multiple cycles every day, handle heavy loads, and process everything from lightly soiled linens to heavily contaminated fabrics. This continuous workload causes faster wear and tear on internal components such as bearings, motors, belts, valves, and electronic control systems. Over time, even the most durable machines begin to show signs of stress if they are not properly maintained.

Heat, water pressure, chemical detergents, and vibration all combine to challenge the strength of internal parts. When one element fails, it often triggers a chain reaction affecting other components. This makes early detection and professional commercial washing machine repair essential for avoiding larger and more expensive failures.

Early Warning Signs of Mechanical Trouble

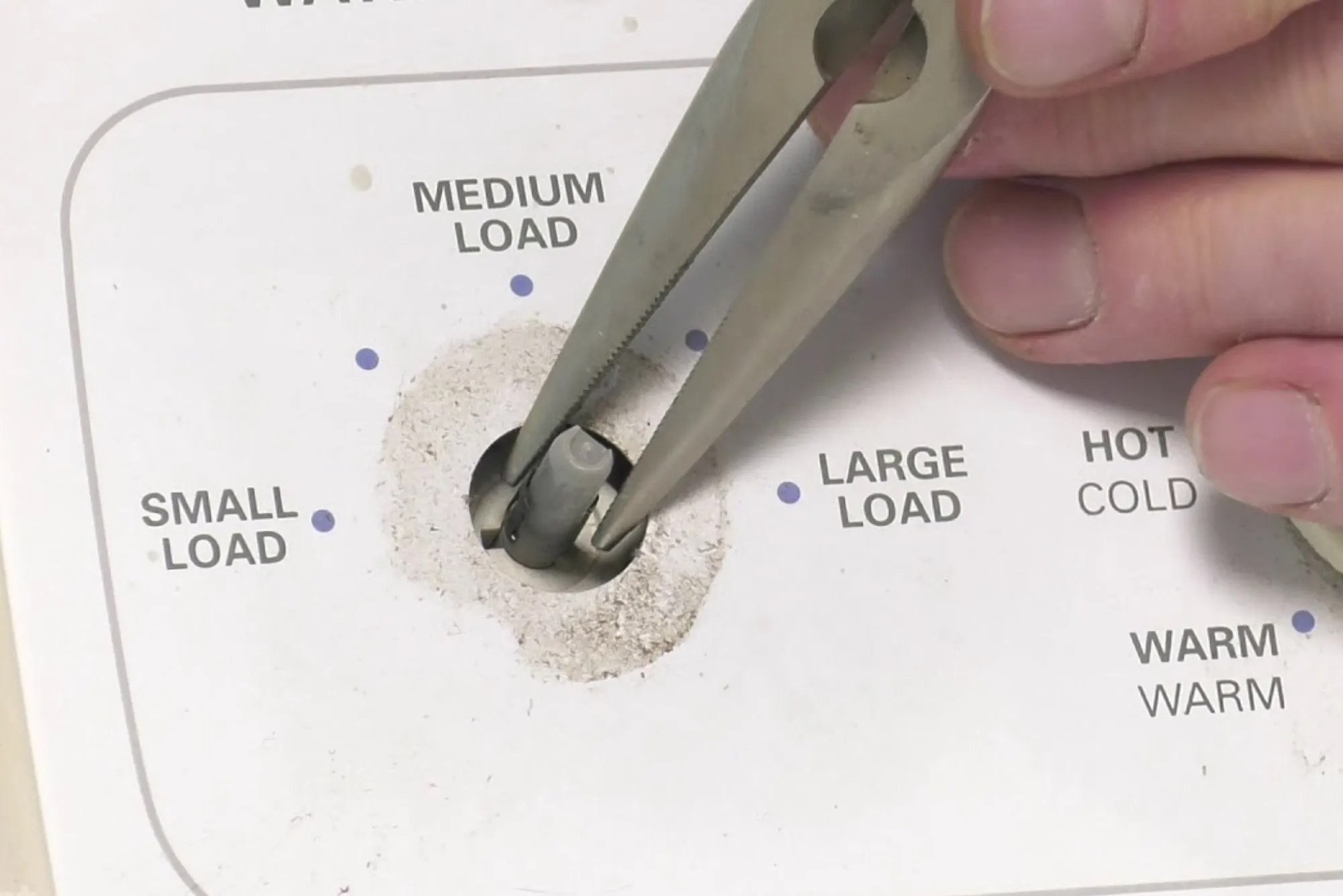

Commercial machines rarely fail without warning. Subtle changes usually appear weeks before a complete breakdown occurs. Unusual noises during operation often signal worn bearings or loose internal parts. Excessive vibration may indicate an imbalanced drum or damaged suspension system. Water that fails to drain properly can point to pump or hose blockages, while poor cleaning results may be linked to temperature control or water inlet issues.

Control errors, random shutoffs, or incomplete cycles often reflect developing electrical problems. Business owners who pay attention to these signs can schedule professional service early, preventing costly downtime. Ignoring these signals usually leads to sudden machine failure at the most inconvenient moment.

The Financial Impact of Delayed Repairs

Postponing repairs is one of the most expensive mistakes businesses make. A malfunctioning washing machine does not only affect one department. In hotels, it disrupts room availability. In hospitals, it influences hygiene standards. In laundromats, it directly impacts daily revenue. Every hour a machine remains offline represents lost income, dissatisfied customers, and operational stress.

Emergency breakdowns also lead to higher repair costs. When a minor issue is neglected, it often damages multiple components, turning a small fix into a major rebuild. Regular inspection and timely commercial washing machine repair protect organizations from unexpected financial shocks while extending the lifespan of expensive equipment.

Why DIY Fixes Can Make the Problem Worse

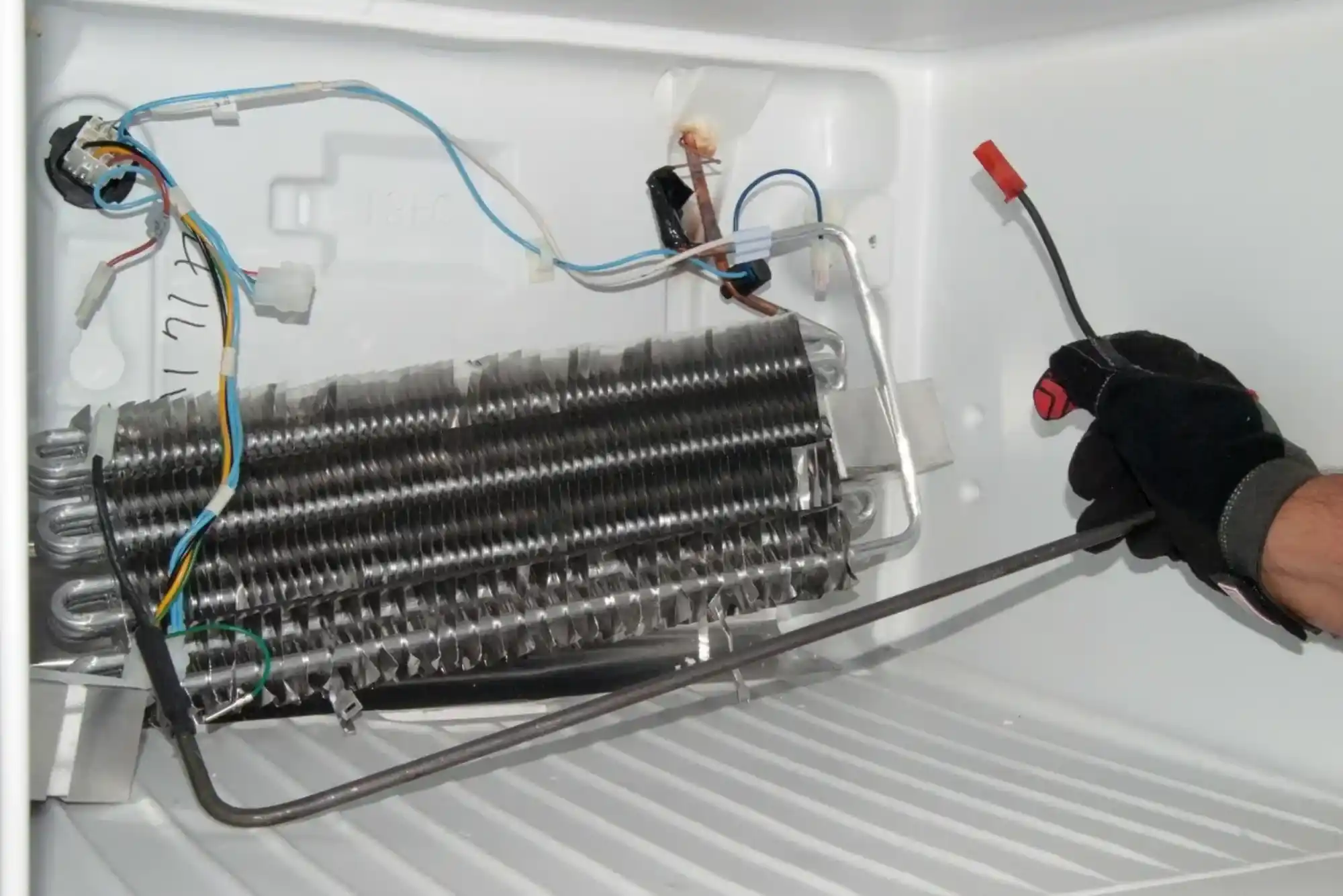

Some business owners attempt temporary fixes to avoid service costs. While understandable, this approach can be risky. Commercial washing machines are complex systems that combine electrical control boards, industrial motors, sensors, pressure valves, and high-capacity pumps. A mistake in handling any of these components can cause further damage, safety hazards, or even complete system failure.

Improper wiring repairs may lead to electrical fires. Incorrect part installation can cause leaks or imbalance. Unauthorized changes may also void manufacturer warranties, leaving the business fully responsible for future repairs. Professional technicians use specialized diagnostic tools and manufacturer guidelines to ensure repairs are safe, accurate, and durable.

How Preventive Maintenance Reduces Breakdown Frequency

One of the most effective ways to avoid frequent breakdowns is preventive maintenance. Routine service checks allow technicians to identify worn parts before failure occurs. Lubrication of moving components minimizes friction. Inspection of hoses and valves prevents leaks and pressure issues. Electrical testing ensures control systems remain stable and accurate.

Preventive maintenance schedules also help maintain energy efficiency. Machines that operate smoothly consume less power and water, reducing utility costs for businesses. Over time, consistent servicing significantly lowers repair frequency and protects the overall value of commercial laundry systems.

The Role of Water Quality in Machine Longevity

Water quality plays a major role in the health of commercial washing machines. Hard water contains mineral deposits that slowly build up inside valves, pipes, and heating elements. These deposits restrict water flow, cause overheating, and reduce washing efficiency. Detergent residue can also accumulate within the drum and drainage system.

Filtration systems and regular descaling treatments help minimize this damage. Technicians performing commercial washing machine repair often identify mineral buildup as a root cause of recurring malfunctions, especially in regions where hard water is common.

Electrical Systems and Control Panel Failures

Modern commercial washing machines rely heavily on electronic control panels. These systems regulate water levels, temperatures, spin speed, and cycle timing. Power surges, moisture exposure, and aging components can damage these sensitive circuits.

When control boards malfunction, machines may freeze mid-cycle, display error codes, or ignore programmed commands. Accurate diagnosis requires advanced testing equipment and software calibration. In many cases, repairing rather than replacing control panels saves businesses significant money, but precision and expertise are essential.

The Importance of Using Original Replacement Parts

The quality of replacement parts directly affects the reliability of future machine performance. Cheap, non-original parts may fit temporarily but often wear out quickly or perform inconsistently. This leads to repeated breakdowns and rising repair costs over time.

Professional technicians insist on using manufacturer-approved parts whenever possible. These components meet the original design standards of the machine, ensuring proper fit, strength, and durability. Investing in quality replacements during commercial washing machine repair reduces repeat failures and stabilizes long-term performance.

How Trained Technicians Diagnose Complex Problems

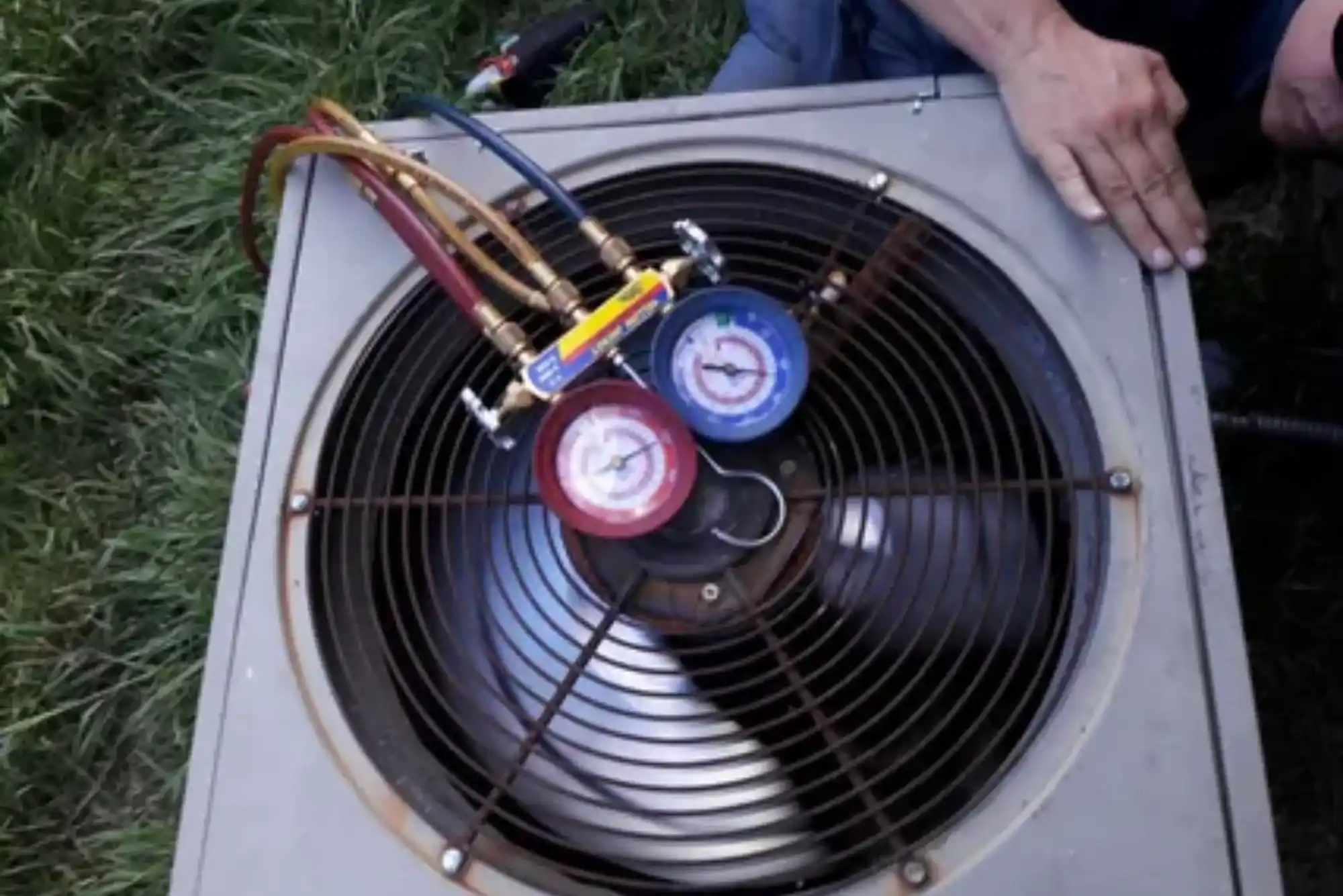

Accurate diagnosis is the foundation of effective repair. Professional technicians begin by analyzing error codes, testing electrical continuity, checking water pressure levels, and inspecting internal mechanical assemblies. They use digital meters, pressure gauges, vibration testers, and manufacturer diagnostic software to pinpoint fault origins precisely.

This structured diagnostic approach avoids guesswork. Rather than replacing multiple parts blindly, technicians target the specific failing component. This reduces repair time, lowers cost, and ensures confidence in the final result.

The Importance of Quick Response for Business Continuity

In commercial environments, time is as valuable as the machines themselves. A delayed repair response can disrupt service schedules, strain staff workloads, and damage customer trust. Fast professional response reduces downtime and allows operations to resume quickly.

Many service providers now offer same-day diagnostics and emergency support. This ensures businesses suffer minimal interruption while protecting brand reputation and service reliability.

Tailored Solutions for Different Industries

Each industry places unique demands on its washing equipment. Hotels require consistent linen quality with high turnover. Hospitals demand strict hygiene compliance through precise temperature control. Fitness centers process heavily soiled towels daily. Laundromats rely on uninterrupted machine availability to serve steady customer flow.

Professional commercial washing machine repair adapts service strategies according to each industry’s operational priorities. This customized approach ensures machines perform optimally within their specific work environment rather than relying on generic repair methods.

How Technician Experience Affects Repair Quality

Experience plays a major role in repair success. Skilled technicians recognize subtle warning signs that less experienced workers might overlook. They understand which components commonly fail in specific machine models and how interconnected systems influence one another.

Experienced professionals also complete repairs faster due to familiarity with internal layouts and component compatibility. Their confidence reduces the risk of trial-and-error attempts that waste both time and money for business owners.

Environmental Efficiency Through Repair

Repairing machines instead of replacing them contributes to environmental sustainability. Commercial equipment contains heavy metals, electronic waste, and industrial plastics that increase landfill pollution when discarded prematurely. Repairing and maintaining existing equipment reduces waste and conserves manufacturing resources.

Energy-efficient components installed during commercial washing machine repair also reduce operational carbon footprints. Businesses that prioritize repair over replacement support long-term environmental responsibility while controlling costs.

Staff Training and Operational Awareness

Machine longevity is influenced not only by mechanical quality but also by how staff members use the equipment. Overloading machines, improper detergent use, slamming doors, and ignoring early warning indicators accelerate wear. Training staff to follow proper operation procedures significantly reduces breakdown frequency.

Technicians often provide operational guidance after completing repairs, helping businesses avoid recurring issues through smarter everyday usage.

Planning a Long-Term Equipment Care Strategy

Successful businesses treat equipment care as a strategic investment, not a reactive expense. Maintaining service logs, scheduling periodic inspections, and budgeting for routine maintenance reduces surprise costs. Tracking previous failures helps identify recurring issues and refine preventive strategies.

With the guidance of reliable service partners, businesses can design long-term maintenance plans that maximize machine lifespan while controlling operating budgets.

Choosing the Right Repair Partner for Long-Term Success

A dependable repair provider offers more than technical skill. They provide clear communication, honest diagnostics, transparent pricing, and post-service support. Businesses benefit when technicians understand the urgency of commercial operations and prioritize service continuity.

A strong repair partnership reduces equipment stress, financial risk, and operational anxiety over time.

The Long-Term Value of Professional Commercial Repairs

Professional commercial washing machine repair protects more than just mechanical systems. It protects business productivity, customer satisfaction, staff efficiency, and long-term profitability. Proper repair restores machines to optimal performance while preventing recurring breakdown cycles.

As machines operate more smoothly, businesses experience fewer service interruptions, lower utility costs, and improved washing quality. Over years of consistent care, repair investments return their value many times over.

The Future of Commercial Laundry Equipment Maintenance

As technology advances, commercial washing machines are becoming more intelligent, energy-efficient, and data-driven. Predictive maintenance software, automated error reporting, and remote diagnostics are slowly entering the industry. These innovations will further reduce downtime and improve service precision.

Even with advanced technology, skilled human technicians will remain essential. Machines can report problems, but trained experts will continue to solve them safely and efficiently.

Final Thoughts on Protecting Your Laundry Investment

Commercial washing machines are not simple appliances. They are productivity engines that support entire business models. When they fail, financial impact follows quickly. Regular maintenance, professional diagnostics, quality replacement parts, and staff awareness form the foundation of reliable equipment performance.

Choosing timely commercial washing machine repair over delayed fixes protects machines from catastrophic damage. It protects businesses from revenue loss. It protects customers from service disruption. Most importantly, it safeguards the long-term success of operations that depend on consistent laundry performance every single day.