A washing machine is one of the most essential household appliances, and when it stops spinning properly, daily life can become inconvenient and stressful. The spin cycle is responsible for removing excess water from clothes, making them lighter, easier to dry, and ready for use. When this function fails, clothes remain dripping wet, cycles take longer, and the appliance may start making unusual noises or stop working altogether. Washing machine spin failure repair is therefore not just a technical requirement but a necessity to restore comfort, efficiency, and reliability in the home.

Spin failure can affect both top-load and front-load washing machines, regardless of brand or model. While the symptoms may appear similar, the underlying causes can vary widely. Professional repair services focus on identifying the exact reason behind the failure and applying a long-term solution rather than a temporary fix. Understanding how spin failure occurs and why expert repair is important helps homeowners avoid repeated breakdowns and unnecessary expenses.

Why the Spin Cycle Is Critical for Washing Performance

The spin cycle plays a vital role in the overall washing process. After the wash and rinse stages, spinning removes most of the water trapped in the fabric. This process not only shortens drying time but also prevents unpleasant odors caused by moisture retention. When the spin cycle does not work correctly, clothes may need to be rewashed or manually wrung, which wastes time, water, and energy.

A properly functioning spin cycle also protects the washing machine itself. Efficient spinning reduces strain on the motor and internal components by ensuring balanced rotation. Washing machine spin failure repair restores this balance, allowing the appliance to operate smoothly and quietly. Over time, neglecting spin-related problems can lead to more severe damage, including motor burnout or drum misalignment.

Early Signs of Washing Machine Spin Failure

Spin failure rarely occurs without warning. Many machines show early symptoms that indicate the need for professional washing machine spin failure repair. These signs may include excessive vibration during the spin cycle, loud banging or grinding noises, cycles that stop before completion, or error codes displayed on the control panel. Clothes coming out wetter than usual is another clear indication that the spin function is not performing as it should.

Ignoring these early signs can cause the problem to worsen. A minor issue such as a loose belt or sensor malfunction can develop into a major mechanical failure if left unaddressed. Timely repair ensures that small problems are resolved before they affect the entire system.

Mechanical Causes Behind Spin Failure

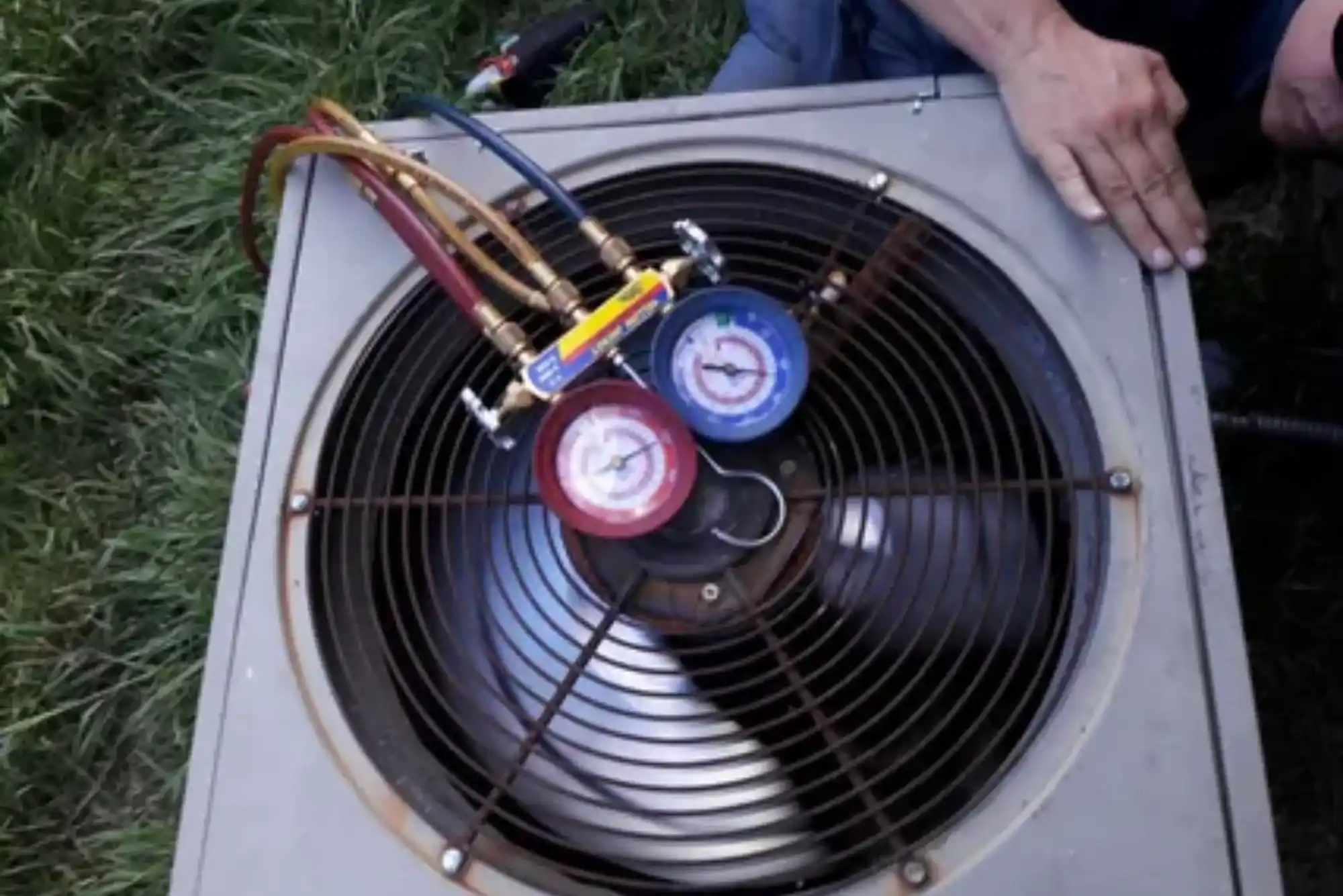

Mechanical wear and tear is one of the most common reasons for spin failure, especially in older washing machines. Components such as drive belts, pulleys, bearings, and motor couplings are constantly under stress due to repeated cycles and heavy loads. Over time, these parts can wear out, slip, or break completely, preventing the drum from reaching the required spinning speed.

Washing machine spin failure repair in mechanical cases often involves replacing worn components with high-quality, compatible parts. Professional technicians carefully inspect the drum assembly and motor connections to ensure everything is properly aligned. This level of precision is essential for restoring smooth spinning and preventing recurring issues.

Electrical and Electronic Issues Affecting the Spin Cycle

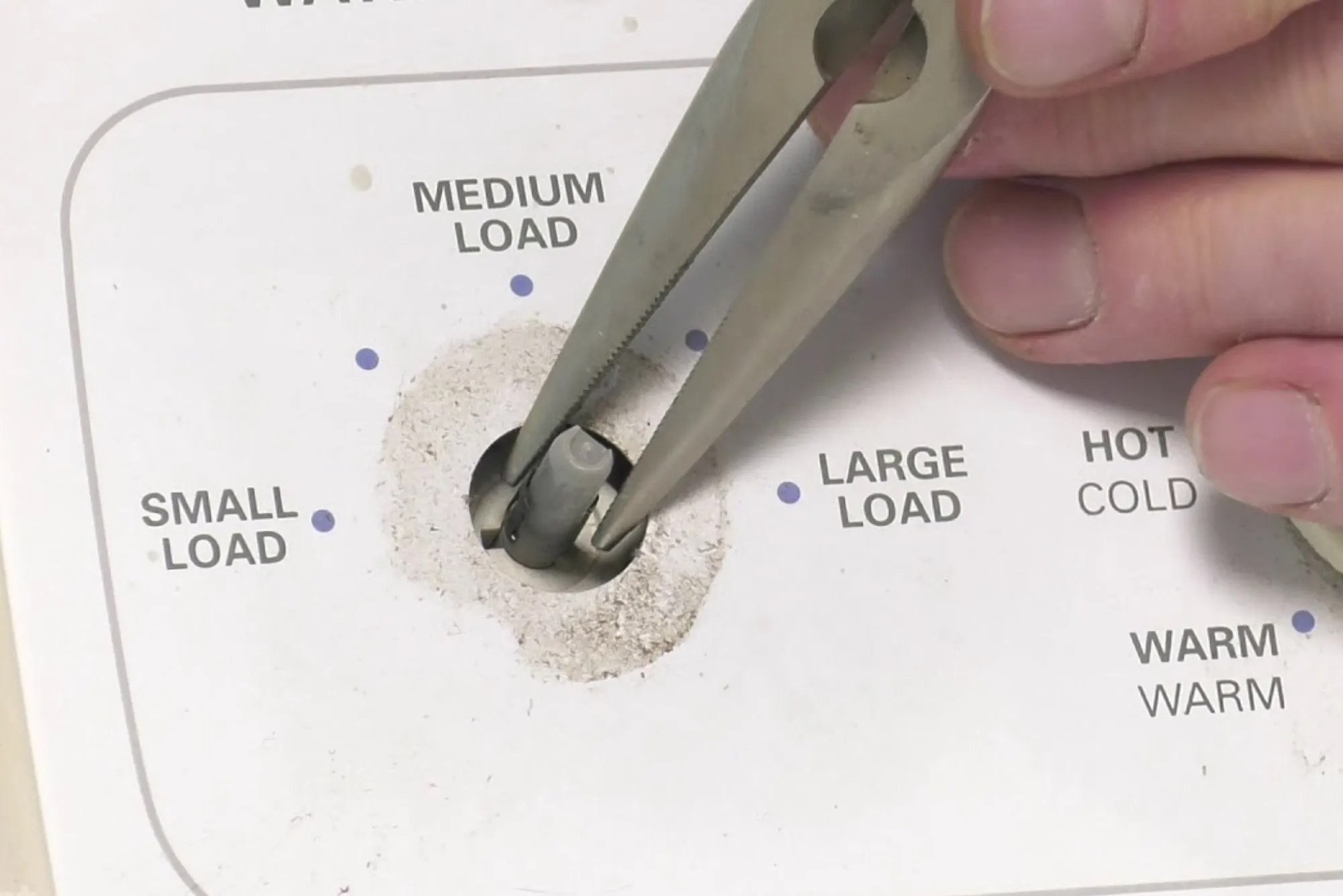

Modern washing machines rely heavily on electronic control systems to manage different stages of operation. Sensors, control boards, and safety switches work together to regulate speed and balance during the spin cycle. When any of these components malfunction, the machine may refuse to spin as a protective measure.

Faulty door locks or lid switches are common electronic causes of spin failure. If the machine does not detect that the door is securely closed, it will not initiate spinning. Washing machine spin failure repair in such cases involves testing and replacing defective switches or sensors to restore normal operation. Control board failures are more complex and require specialized expertise, making professional repair essential.

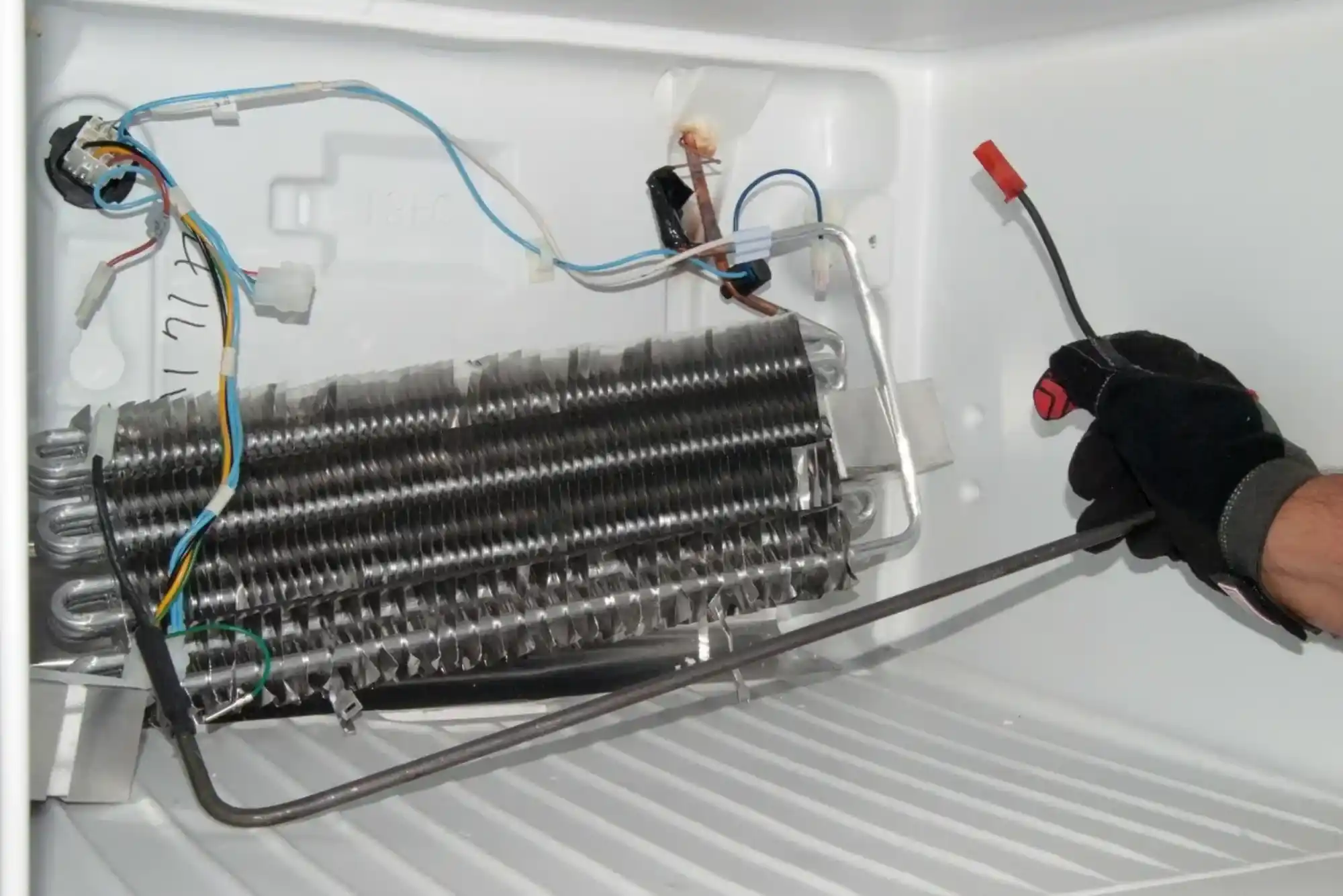

The Impact of Drainage Problems on Spinning

A washing machine is designed not to spin if water remains inside the drum. Drainage issues are therefore closely linked to spin failure. Blocked drain hoses, clogged filters, or malfunctioning drain pumps can prevent water from exiting the machine, stopping the spin cycle altogether.

Professional washing machine spin failure repair includes a thorough inspection of the drainage system. Technicians remove blockages, repair or replace damaged pumps, and ensure that water flows freely during operation. Proper drainage not only restores spinning but also protects the machine from water-related damage.

Imbalance and Overloading Issues

Improper loading is another significant factor that contributes to spin failure. When clothes are unevenly distributed or the machine is overloaded, the drum may become unbalanced. Most modern machines are programmed to stop spinning if excessive imbalance is detected to prevent damage.

Repeated imbalance can weaken suspension components and shock absorbers over time. Washing machine spin failure repair addresses these issues by repairing or replacing damaged suspension parts and advising users on proper loading techniques. Correct usage plays an important role in maintaining long-term performance.

Professional Diagnosis and Repair Approach

Effective washing machine spin failure repair begins with accurate diagnosis. Professional technicians use advanced tools and diagnostic methods to identify the root cause of the problem. This process includes checking error codes, inspecting mechanical parts, testing electrical components, and evaluating overall machine performance.

Once the issue is identified, repair work is carried out with precision and care. Whether it involves motor replacement, belt adjustment, sensor repair, or control board servicing, professional repair focuses on restoring the appliance to optimal working condition. After repairs are completed, the machine is tested thoroughly to ensure the spin cycle operates smoothly and safely.

Advantages of Professional Washing Machine Spin Failure Repair

Hiring professional repair services offers significant advantages over attempting DIY solutions. Washing machines are complex appliances that combine mechanical motion with electrical control systems. Incorrect handling can lead to further damage or safety hazards.

Professional washing machine spin failure repair ensures that repairs are done correctly the first time. Experienced technicians understand different brands and models, allowing them to apply the most effective solutions. This approach saves time, reduces costs, and extends the lifespan of the appliance.

Safety Considerations During Repair

Safety is a critical aspect of washing machine repair. The appliance operates at high speeds during the spin cycle and involves electrical components that require careful handling. Attempting repairs without proper knowledge can result in electric shock, injury, or damage to the machine.

Professional technicians follow strict safety protocols when performing washing machine spin failure repair. They disconnect power sources, use appropriate tools, and ensure all components are securely installed before testing the machine. This level of care protects both the user and the appliance.

Long-Term Benefits of Timely Repair

Addressing spin failure promptly offers long-term benefits beyond immediate functionality. A properly repaired washing machine operates more efficiently, consumes less energy, and produces better washing results. Timely washing machine spin failure repair also prevents secondary damage that could lead to costly replacements.

Regular maintenance and professional servicing contribute to consistent performance and reliability. Homeowners who invest in timely repairs often enjoy years of trouble-free operation, making professional repair a cost-effective solution.

Preventive Maintenance After Spin Failure Repair

After completing washing machine spin failure repair, preventive maintenance plays a key role in avoiding future issues. Proper loading, routine cleaning of filters, and periodic inspection of hoses and belts help maintain optimal performance. Professional technicians often provide guidance on best practices to reduce wear and tear.

Preventive maintenance not only protects the spin function but also improves overall washing efficiency. By following recommended usage and servicing schedules, users can maximize the lifespan of their washing machine.

When Spin Failure Requires Immediate Attention

Certain spin failure symptoms require immediate professional attention. Burning smells, loud metallic noises, or complete cycle stoppage indicate serious internal problems. Continuing to use the machine under these conditions can cause irreversible damage.

Seeking professional washing machine spin failure repair at the first sign of trouble ensures that issues are resolved safely and effectively. Prompt action minimizes downtime and prevents inconvenience caused by prolonged appliance failure.

The Role of Expert Technicians in Quality Repair

Expert technicians bring experience, technical knowledge, and problem-solving skills to washing machine spin failure repair. They understand how different components interact and how small faults can affect overall performance. Their expertise allows them to provide durable solutions that restore confidence in the appliance.

Professional repair services also offer accountability and quality assurance. This level of service ensures that repairs meet industry standards and deliver reliable results.

Washing machine spin failure repair is an essential service for maintaining the efficiency, safety, and performance of one of the most important household appliances. Spin failure can result from mechanical wear, electrical faults, drainage problems, or improper usage, all of which require expert diagnosis and repair. Professional repair services provide comprehensive solutions that address the root cause of the problem and restore smooth spinning operation.